5 Tips for Efficient Warehouse Management with P&G and DHL

Warehouse management is a critical component of logistics and supply chain management, ensuring products from Procter & Gamble (P&G) and DHL reach customers swiftly and efficiently. Here are five essential tips for enhancing warehouse operations:

1. Optimize Layout and Space Utilization

Effective space management is key to warehouse efficiency. Here’s how you can achieve this:

- Vertical Storage Solutions: Implement tall shelves or automated vertical lift systems to reduce the space footprint.

- Zone Picking: Divide the warehouse into zones for different categories of products, streamlining the picking process.

- Dynamic Slotting: Regularly update product placement based on sales velocity and turnover rates.

2. Implement Advanced Technology

In today’s digital age, leveraging technology can greatly improve warehouse efficiency:

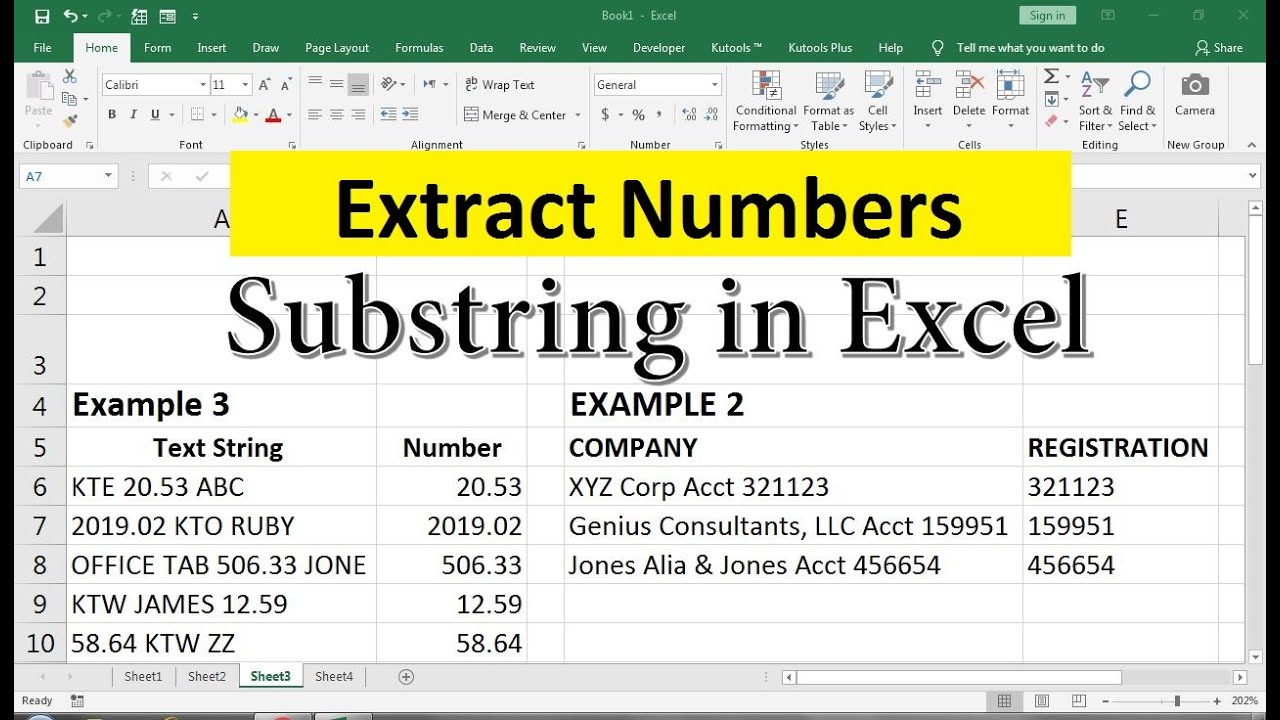

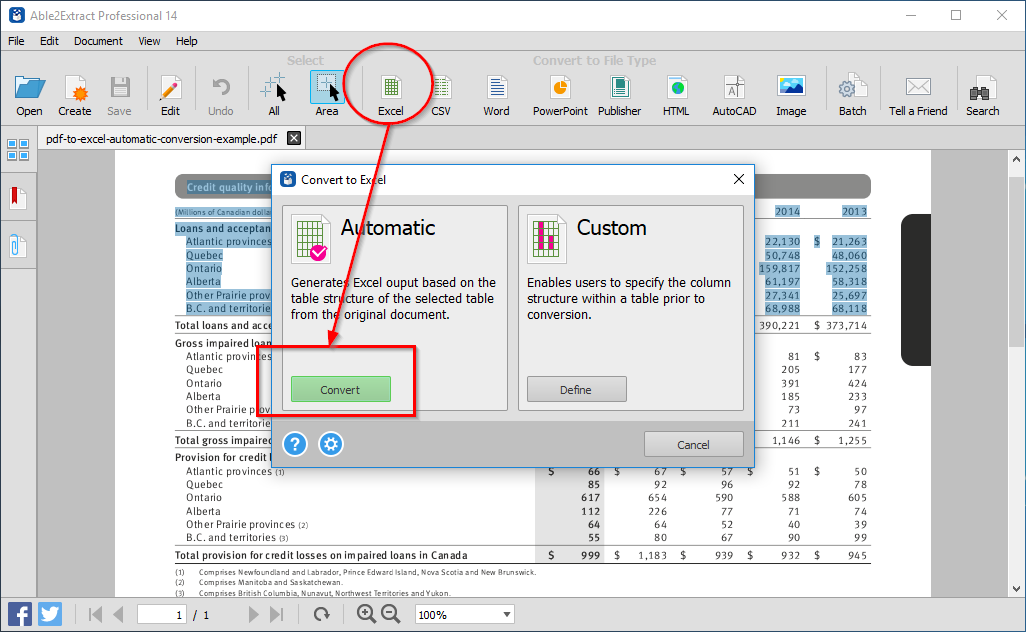

- Warehouse Management Systems (WMS): Utilize WMS for real-time inventory tracking, order optimization, and logistics management.

- Automated Guided Vehicles (AGVs): These robots assist in moving goods within the warehouse, reducing labor costs and errors.

- Radio-Frequency Identification (RFID): Enhance inventory accuracy and reduce the time for stock checks.

3. Focus on Employee Training and Safety

A well-trained workforce is the backbone of an efficient warehouse:

- Regular Training: Keep staff updated with the latest practices, technologies, and safety protocols.

- Ergonomic Workstations: Design workstations to prevent injury and increase worker efficiency.

- Safety Compliance: Maintain a safe working environment with clear signage, proper lighting, and safety gear.

4. Enhance Picking Efficiency

Efficient picking can significantly boost productivity:

- Batch Picking: Group orders together to minimize travel distance within the warehouse.

- Wave Picking: Release orders in waves, optimizing the picking process for time and labor.

- Pick-to-Light Systems: Use lights to guide pickers to the exact location of items, reducing errors and speeding up the process.

5. Regular Performance Analysis

Constant evaluation of warehouse operations is vital:

- Key Performance Indicators (KPIs): Track metrics like picking accuracy, inventory turns, and order cycle times.

- Continuous Improvement: Use data to identify inefficiencies and implement changes to optimize operations.

- Benchmarking: Compare performance against industry standards or competitors to identify areas for improvement.

💡 Note: Efficient warehouse management isn't just about storage; it's about creating a seamless flow of goods from receiving to shipping, enhancing customer satisfaction and operational profitability.

By implementing these strategies, you'll not only improve warehouse operations but also align with the advanced logistics practices of companies like P&G and DHL, ensuring that your warehouse becomes a model of efficiency in the supply chain landscape.

What are the key benefits of implementing RFID technology in a warehouse?

+RFID helps in real-time tracking of inventory, reducing the risk of stock discrepancies, speeding up inventory audits, and improving pick accuracy.

How often should I reconfigure my warehouse layout?

+Regular reconfiguration can be beneficial, ideally every 6-12 months or as product lines and volume change, to ensure optimal space usage.

Can small warehouses also benefit from automation?

+Yes, smaller warehouses can greatly benefit from automation with solutions like mobile picking robots or conveyor systems tailored to their size.

What’s the impact of poor employee training on warehouse efficiency?

+Untrained or improperly trained employees can lead to higher error rates, reduced productivity, increased safety risks, and ultimately, higher operational costs.

Is continuous improvement really necessary in warehouse operations?

+Continuous improvement ensures that your warehouse operations adapt to market changes, new technologies, and consumer demands, keeping you competitive and efficient.