Control Chart Creation Guide in Excel

In the world of quality control and process improvement, a control chart serves as an essential tool for monitoring variations in processes and identifying when a process is going out of control. Excel, with its robust data manipulation and visualization capabilities, provides an excellent platform for creating control charts. This guide will walk you through the detailed process of setting up a control chart in Excel, ensuring you can effectively track and analyze your data's stability over time.

Understanding Control Charts

Before diving into Excel, let’s briefly discuss what control charts are:

- Control Chart: A graphical display of process data over time, showing upper and lower control limits and a central line (often the mean) to help determine process stability.

- Types: There are various types of control charts depending on the data type (e.g., Individual, X-Bar, R, S, etc.), but we’ll focus on creating a simple X-Bar and R chart, suitable for analyzing the mean and range of subgroups of data.

Preparing Your Data

To create an effective control chart, you need to:

- Collect data in a systematic manner:

- Decide on the frequency of data collection (e.g., hourly, daily).

- Ensure each data point or subgroup is representative of the process at that time.

- Organize your data in Excel:

- Calculate:

- Mean (X-Bar) for each subgroup

- Range ® for each subgroup

| Sample ID | Value 1 | Value 2 | … | Value n |

|---|---|---|---|---|

| 1 | 45 | 50 | … | 48 |

| 2 | 46 | 53 | … | 50 |

Setting Up the Control Chart in Excel

Here’s how to construct your control chart:

- Open Excel and input your data.

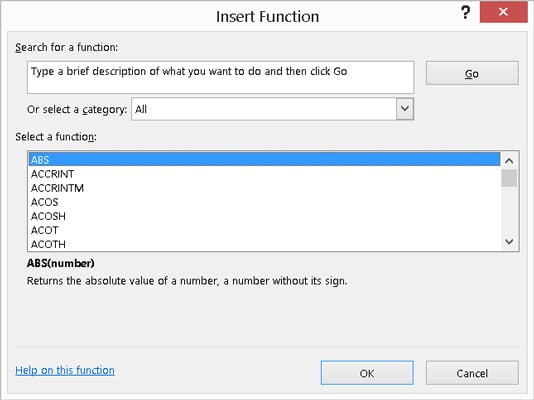

- Calculate Statistical Values:

- Mean of Subgroup Means (X-double bar): =AVERAGE(E2:E10) if your means are in column E.

- Mean of Subgroup Ranges (R-bar): =AVERAGE(F2:F10) if your ranges are in column F.

- Determine Control Limits:

- Upper Control Limit (UCL) for X-bar: =D4 + (3 * F4/AVERAGE(F2:F10)). Here, D4 is X-double bar, F4 is R-bar, and AVERAGE(F2:F10) assumes you have 9 subgroups.

- Lower Control Limit (LCL) for X-bar: =D4 - (3 * F4/AVERAGE(F2:F10))

- Similarly, calculate UCL and LCL for Range charts.

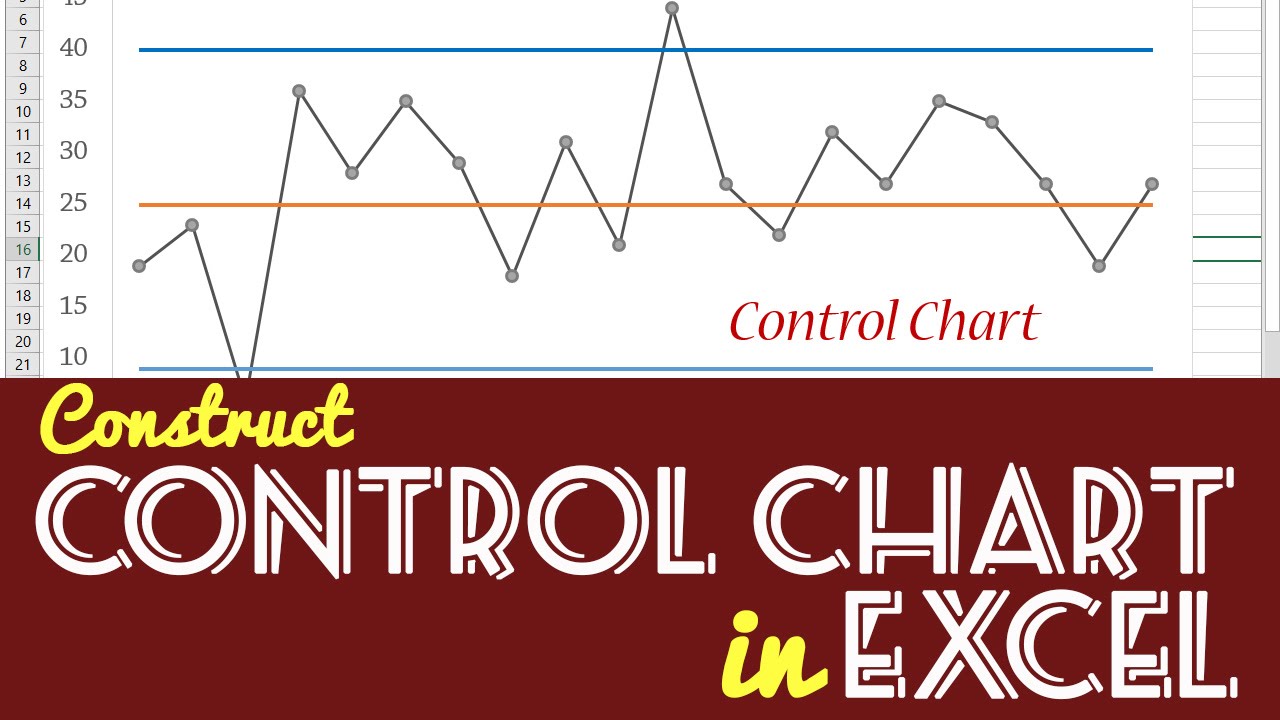

- Create the Chart:

- Select your data including means, ranges, and control limits.

- Go to ‘Insert’ > ‘Scatter Chart’ > ‘Scatter with Straight Lines.’

- Format the chart:

- Add series for UCL, LCL, and central lines.

- Adjust the chart title, axis titles, and gridlines for clarity.

- Interpretation: Look for points outside of the control limits or patterns that might indicate a process that’s out of control.

⚠️ Note: Ensure your data is free from errors as control charts are sensitive to data outliers.

Advanced Features in Excel for Control Charts

- Data Validation for input consistency.

- Conditional Formatting to highlight points beyond control limits automatically.

- Macros or VBA for automated calculation and plotting.

The process of creating a control chart in Excel goes beyond mere data visualization; it encompasses understanding process variability, identifying anomalies, and making informed decisions for quality improvement. With these insights, organizations can better control processes, leading to higher efficiency and reduced variability, which ultimately enhances customer satisfaction and reduces costs.

FAQs

What does it mean if a point falls outside the control limits?

+If a point falls outside the Upper Control Limit (UCL) or Lower Control Limit (LCL), it indicates a ‘special cause’ variation, suggesting that an unusual event or error has occurred that needs investigation.

How do I decide on the subgroup size for my control chart?

+The subgroup size depends on several factors including the process’s natural variability, how often you can collect data, and the stability you aim to measure. Commonly, subgroups of 4-5 data points are used to balance sensitivity and practicality.

Can I create a control chart in Excel without using macros?

+Yes, you can create control charts manually in Excel without macros, though using macros can streamline repetitive tasks and enhance functionality.

The creation of control charts in Excel not only helps in visualizing data trends but also in fostering a culture of continuous improvement. As you implement these charts, remember that the real value lies in interpreting the data and taking action based on the insights gained. Ensuring your processes are monitored and optimized regularly will pave the way for sustained quality excellence.

Related Terms:

- Control Chart in Excel template

- Control chart in Excel pdf

- Simple Control Chart template Excel

- free excel control chart template

- control chart in excel template

- microsoft excel control chart template