5 Simple Steps to Calculate Cpk in Excel

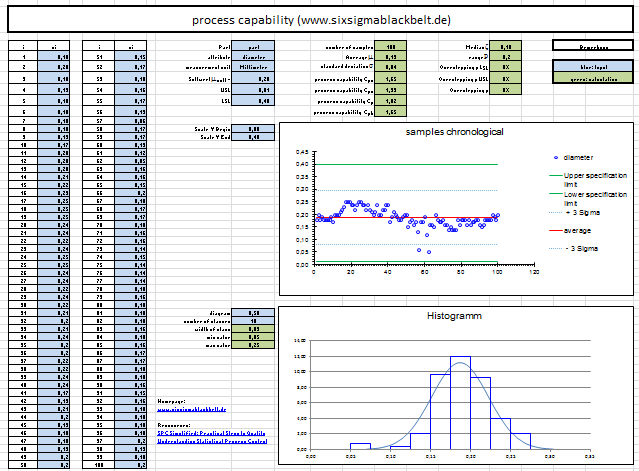

Calculating Cpk (Process Capability Index) in Excel can greatly enhance your understanding of process variability, helping to ensure the consistency and quality of your production or services. Here are five straightforward steps to calculate Cpk in Excel, aimed at quality control professionals, production engineers, and anyone interested in statistical process control:

1. Gathering Necessary Data

Before diving into Excel calculations, you need the right data:

- USL (Upper Specification Limit): The highest allowable value of the output.

- LSL (Lower Specification Limit): The lowest allowable value of the output.

- Process Data: A set of measurements or sample data points from your process.

Collect these values and ensure they are reliable to produce meaningful results.

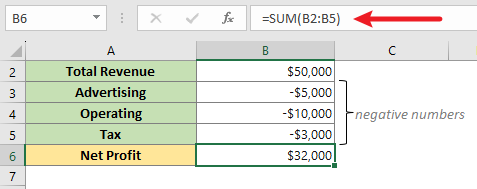

2. Setting Up Your Excel Spreadsheet

Here’s how you can structure your Excel sheet for Cpk calculation:

| Column A | Column B |

|---|---|

| 1 | Sample Values |

| 2 | Mean |

| 3 | Standard Deviation |

| 4 | Cpk |

🔎 Note: Use separate cells for USL and LSL values.

3. Calculating Mean and Standard Deviation

Calculate the mean and standard deviation for your dataset:

- Mean: Use the AVERAGE function on your data, for instance, if your data is in cells B1 through B100, enter

=AVERAGE(B1:B100)in the ‘Mean’ cell. - Standard Deviation: Use the STDEV.S or STDEV.P function, depending on whether your data represents a sample or the entire population. For sample data, enter

=STDEV.S(B1:B100)in the ‘Standard Deviation’ cell.

4. Calculating Process Performance Index

Now, calculate the following:

- Process Sigma: Divide the absolute difference between USL and LSL by six. Input

=(USL-LSL)/6in an empty cell, let’s say E2. - Cpu: Calculate the upper capability index as

=1.5(USL-Mean)/Standard Deviation, typically in E3. - Cpl: Calculate the lower capability index as

=1.5(Mean-LSL)/Standard Deviation, which you can put in E4.

These formulas ensure that you’re considering both the upper and lower limits of your process capability.

5. Determining the Cpk

The Cpk value is the minimum of Cpu and Cpl. Here’s how to find it:

- In Excel, use the MIN function to determine the smaller of Cpu or Cpl. For example,

=MIN(E3,E4).

Now you have the Cpk value, which indicates how well your process can fit within the specification limits.

Calculating Cpk in Excel is not just about following steps but understanding what these numbers mean for your process:

- A Cpk of 1.0 or greater suggests the process is capable of meeting customer requirements.

- A Cpk greater than 1.33 is generally considered good, showing a capable process with room for minor variation.

- A Cpk below 1.0 indicates potential quality issues, prompting you to investigate further and potentially improve your process.

Using Excel for Cpk calculation enables quick analysis and periodic checks on your process’s health. Here are some final thoughts:

- Regular Monitoring: Don’t forget to monitor your process capability over time. Variation can creep in silently.

- Process Improvement: If your Cpk is low, identify process steps where improvement can be made. Lean or Six Sigma methodologies can be useful here.

- Accuracy: Ensure the accuracy of your data. Measurement errors or outliers can significantly affect your Cpk value.

What does a low Cpk value indicate?

+A low Cpk value indicates that your process is not producing outputs within the desired specification limits consistently, suggesting a need for process improvement or recalibration.

Can Cpk be calculated for any process?

+Cpk can be calculated for any process where you have specification limits (USL and LSL) and a set of measured data points. However, the meaningfulness of Cpk depends on how well these limits and data represent the process’s performance.

How often should I calculate Cpk?

+The frequency of Cpk calculation depends on the criticality of the process. For stable processes, quarterly or annual checks might suffice, but for critical or frequently changing processes, more regular checks, perhaps monthly or even weekly, are recommended.